Corewise vs. Almonte:

Features, Reviews & Comparison

Comparison Between Almonte v Corewise Core Saws

The invention of the automatic core saw was created by Frank Frisina in Perth, 1995.

Frank built his first automatic core saw and branded it Almonte, named after his two children, Al & Montana.

Sales was good all over the world.

Differences Between Almonte & Corewise

Either way you look at it, the Almonte was, and still is, a highly successful saw.

Whatever Frank set his hand to do, he made sure it was good.

So fundamentally, the shape and size of the core saw never changed when the Corewise was created.

However, Frank did listen to core saw operators’ feedback and acted on their needs.

The major improvements were the core saw control panel, the feed chain and the ease of maintenance.

Core Saw Control Panel

The first improvement that was made was the ability to adjust the speed of the feed chain & motor from the inbuilt LCD screen.

This can be changed immediately by unqualified personnel and without calling a qualified electrician.

When cutting different rocks, the Corewise LCD screen will advise the operator on the correct feed speed for the level of hardness of the core.

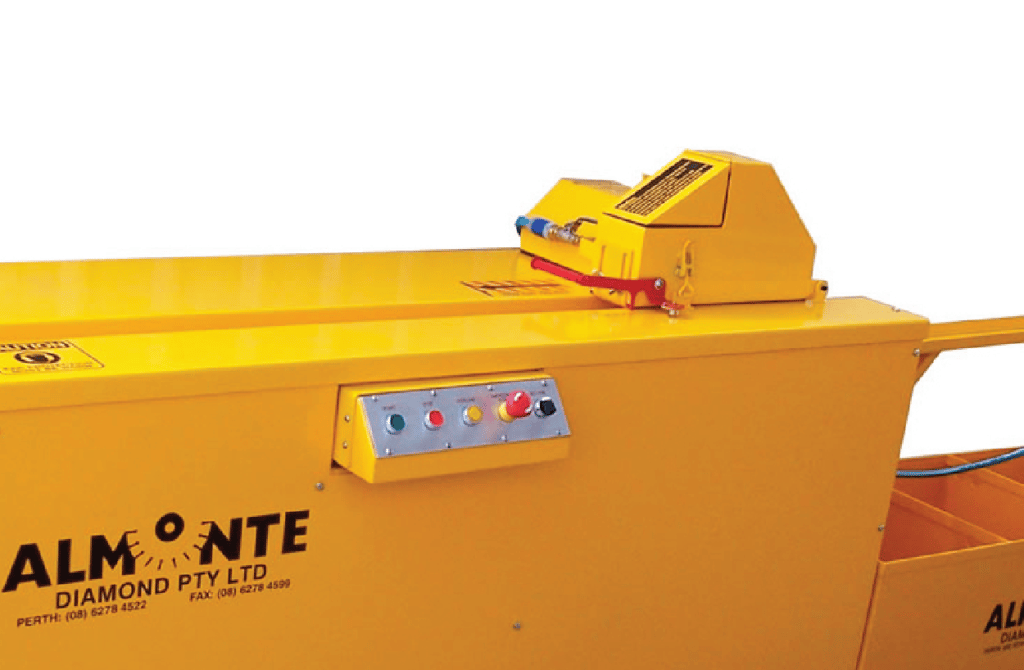

Also in conjunction with Mount Isa Mines, they advised they were forever breaking the $58 push buttons, which are situated smack in the high activity area on the saw.

Loaded core trays, core boats, operators’ legs and core inevitably get dropped or ran into them.

Yep, running into this angular box with your thigh is a similar experience to running into a towbar with your shin – been there done that!

When a single button is damaged, or you’ve punched it out of frustration because it’s given you a dead leg for the third time today, this small cost problem renders the entire saw inoperable for a few days.

From Frank’s service records, buttons were in the top 3 replacement parts.

The Corewise has eliminated button breakages caused in this manner.

One thing that’s good to be aware of, is that Westernex & The Almonte are putting the note below on their quotations:

PLEASE NOTE:

Currently the only saw that conforms to Section 57 of the Code of Practice Safeguarding of Machinery & Plant Under the Occupational Safety & Health Act is the Almonte.

The reason Almonte are led to believe theirs is the only conforming saw can be found in their recently published article.

The Almonte has the control panel IP66 rated waterproof buttons on the front of the saw for the operator to comply with Section 57 of the Code of Practice Safeguarding of Machinery & Plant Under the Occupational Health & Safety Act, which states that one should not have to lean across a moving part (such as the chain) to operate or stop the machine in the event of an emergency. The Almonte is the only core saw currently manufactured in Australia that complies with the act.

Unfortunately this is a misguidance. The Corewise complies to Section 57.

You are able to see from the above video there is no leaning over the moving parts.

Another reason that the Corewise moved the buttons is due to the below section of the Code of Practice:

CODE OF PRACTICE – SAFEGUARDING OF MACHINERY AND PLANT

Emergency stop devices

Ensure emergency stop devices are:

* Prominent, clearly and durably marked and immediately accessible to each operator of the plant;

* Have handles, bars or push buttons that are coloured red. Labeling can also be used. Consider installing ones that protrude and are not level with the surrounds; and

* Not affected by electrical or electronic circuit malfunction.

Other considerations include:

* The best access for workers;

* The environment the machine is used in, for example whether there could be exposure to dust, chemicals, extremes of temperature or vibration;

* The number of emergency stop devices required. If the machine or plant is large, several devices or pull wires may be necessary;

* A manual procedure for resetting an emergency stop device. They should not be affected by electrical or electronic circuit malfunction; and

* Testing at regular intervals to ensure they have not ceased functioning.

This refers to the ‘Emergency Stop’ button and exposure to dust.

Less dust settles on the buttons when the buttons are closer to eye height, meaning the Emergency Stop won’t get ingrained with dust and not work when needed.

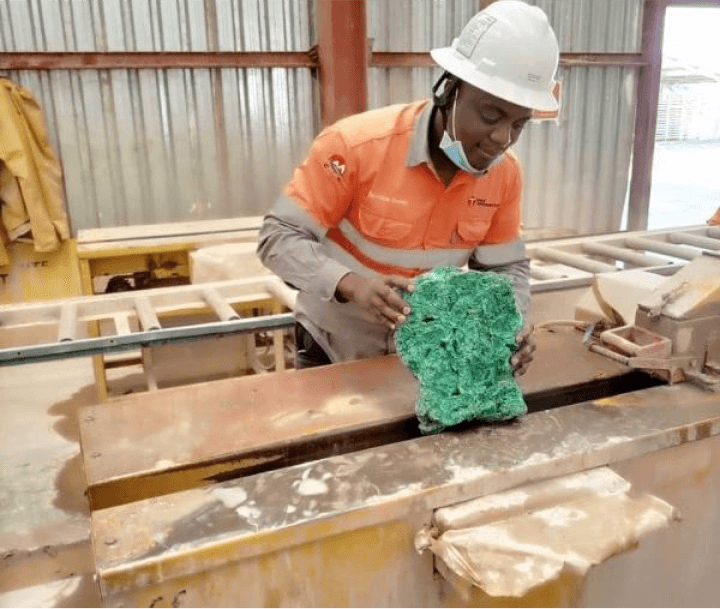

Below is an example of an operation in Africa that has deployed an aftermarket cover to stop the buttons from getting dust ingrained and water damaged. On Frank’s new Corewise this isn’t an issue.

Feed Chain System

Again, from feedback gathered from core saw operators, it was reported the feed chain worked just fine, but with some fine tuning could be even better.

The Almonte saw functions with a ‘pusher’ style feed chain.

The pushers are evenly spaced along the chain and they push the core boats through the blade.

The purpose of using an auto saw is to enhance efficiency.

Operators were finding that if you missed the pusher on the way past, you had to wait for the next come-around.

Corewise solved this by implemented a continuous chain that the ‘teeth’ on the core boat locked into.

This meant the core boat could be placed anywhere on the chain, safely and with ease.

Finally, operators reported that jams were another lost time frustration. Let’s check how Frank solved this on the Corewise with the anti-jam feature:

Ease of Maintenance

Downtime on mine sites can be a massive drain.

Frank saw the need for trained users on-site to perform their own maintenance program easily.

He started with the external grease points.

Now you don’t have to open the entire core saw paneling to grease the bearings, which, because it’s not easy, doesn’t have to happen often.

Also, the blade cover is manufactured from stainless steel instead of the old method of using HD steel and powder coating it.

You can use a magnet to test what yours is, as sooner or later the Almonte will likely upgrade, but until recently it’s still HD steel.

The reason for this was due to the continuously wet environment the saw was used in.

The Corewise wouldn’t rust out.

2023 Sees the Dawn of the Direct Drive

Trust Dynamics to make an already great product even greater.

Corewise now comes with a Direct Drive System – the motor is directly connected to the core saw blade’s through a shaft, which eliminates many of the torque losses associated with the v-belt drives of the old model.

The result? There’s an improved torque transmission, resulting in at least 30% more cutting speed.

It’s also now much easier to run. With no belts to replace, there is way less downtime for maintenance.

Another enhancement? There’s a new mist guard that emits little to no silica mist, rendering the Corewise safer than before. Your operator can breathe better.

Automatic Core Saw Warranty

Both Corewise and Almonte websites state they offer a 12-month warranty.

Both only apply to the motor and gearbox components under normal operating conditions.

Difference is, with the Almonte, you are not granted the flexibility of using the Core Blades or Core Boats of your choice.

Even if you know your preferred Blades or Boats perform better through fair trial and error, Almonte still states “this will void warranty”.

Something to think of upfront.

If you have the Almonte and it’s older than 12 months, we are unsure if this is still relevant, as warranty no longer covers you regardless.

You may then have flexibility of choice?

The Corewise, in comparison, states they offer an unconditional 12-month warranty.

We understand they view a diamond core blade and core boat as a universal component, in which the operator should be allowed personal preference.

The warranty on the Corewise is not voided through using your blade and boat of preference.

You can also trial the Corewise for 30 days.

If you are not 100% happy with the performance, you can return the machine with no further obligations.

It’s zero risk to you.

Conclusion

We trust this helps in your buying decision process.

At Dynamics, we believe both Almonte or Corewise brands deserve respect.

In our opinion, it seems you get greater ‘bang-for-buck’ with the Corewise, but overall you will get many cutting hours out of either machine.

In Australia, at the current time, Almonte exclusively distributes their core saw through Westernex, and don’t offer anyone else this distribution.

For Corewise, you purchase the Corewise saw directly through Dynamics/Corewise partnership. Corewise is the manufacturing arm, while Dynamics takes care of the sales & service.

Frank Frisina, the original inventor of both Almonte and Corewise, is still very much integrated in the manufacture process and available to talk to at anytime.

At Dynamics, the division is headed up by John Hitch for sales or after sales service, along with the Dynamics Customer Happiness Team.

Update: Almonte Westernex Response

We are pleased to announce that this article received a response from Almonte Westernex Team.

As always, our object is not to force you into using one or the other; it’s about giving you the most unbiased info in the industry.

Their response will help this effort for you to form your own decision.

Read about the Almonte Response Here

If you’re looking for an official quotation on the Corewise Automatic Core Saw, simply request quote from the Corewise Automatic Core Saw Page by clicking the button below.

Our Customer Happiness Team typically responds within 6-8 business hours.

You may also be interested in the fully air-conditioned and insulated core cutting containers.

If you want to try it before purchase, we have units for hire. We encourage you to experience its comforts and convenience for yourself first and hope that helps with your buying decision.

Have any more questions about automatic core saws?

Leave them for us in the comments and we will answer them as soon as possible!